TCS John Huxley Pivots from Roulette Wheels to PPE to Help Coronavirus Fight

Posted on: April 13, 2020, 03:46h.

Last updated on: April 13, 2020, 05:00h.

Global casino equipment provider TCS John Huxley (TCSJH) is playing its part in the fight against the coronavirus in its native UK.

More accustomed to supplying the world with roulette wheels, TCSJH has become a temporary manufacturer and supplier of personal protection equipment (PPE) to healthcare workers.

Amid a global shortage of protective equipment (and a temporary slump in demand for roulette wheels), the York, England-based company has realigned its 3d printer to produce vital plastic face shields for the country’s National Health Service (NHS).

The news comes as the Royal College of Nursing (RCN) piled pressure on government ministers to ensure hospitals had all the PPE they needed. RCN said Sunday that nurses could refuse to treat patients with COVID-19 if they can’t access full PPE, although the college stressed this would be “a last resort.”

With its tightest coronavirus restrictions now lifted, China — the traditional global supplier of PPE — is focusing its manufacturing might on churning out vital protective equipment. But in the global rush to buy, the supply chain is chaotic.

In the meantime, many governments are looking for a temporary fix closer to home — manufacturers that can use 3d printers to create masks, gloves, and gowns using designs that have already been vetted and approved for clinical use.

TCSJH said will be able to provide “many thousands” of masks, which will provide protection to frontline staff until larger manufacturers can ready large supplies of injection-molded versions.

Call to Arms

The company’s CEO Tristan Sjöberg said in an official statement that he was proud of his product development team, which was the first to highlight the company had the manufacturing capability to produce PPE.

“We are very pleased to be able to contribute ever so slightly to keep the NHS heroes, who risk their lives on the line every day, a little bit safer,” he added.

Sjöberg called on other gaming equipment manufacturers to see if they, too, could switch production or repurpose resources to support the fight.

Some 80 percent of the world’s roulette wheels are built by TCSJH and its closest competitor, Cammegh, also a UK company.

Constructing a roulette wheel is no simple process. The engineering needs to be scientifically precise, right down to the weight and design of the bearings.

A tilt in the wheel of less than a degree will cause a bias, which means the balls tends to fall in a specific area of the wheel slightly more frequently. Even the smallest of biases can expose a casino to exploitation by mathematically astute gamblers.

Both TCSJH and Cammegh’s methods and specifications remain closely guarded industrial secrets.

‘Unprecedented Challenges’

With most of the world’s casinos shuttered, these are tough times for casino suppliers. Nevada-based Scientific Games (SG) said last week it was working hard to preserve “as many jobs as possible” during what CEO Barry Cottle described as “unprecedented challenges” for the industry.

As one of the biggest casino suppliers in the world, Cottle said SG has the liquidity to weather the crisis.

But many smaller companies aren’t so lucky. The Las Vegas Review-Journal reported that gaming equipment manufacturer Everi has furloughed employees and cut salaries. Its CEO, Michael Rumbolz, has said he is now working for nothing.

Related News Articles

Bragg Gaming Aiming for Nasdaq Listing, Planning Reverse Split

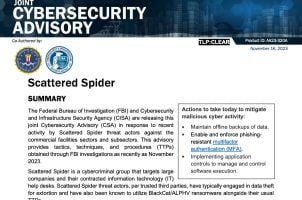

FBI Issues Cybersecurity Advisory on Group that Targeted MGM, Caesars

Most Popular

Las Vegas Overstated F1 Race’s Vegas Impact — Report

Vegas Strip Clubs Wrestle in Court Over Animal Names

Most Commented

-

End of the Line for Las Vegas Monorail

— April 5, 2024 — 90 Comments -

Mega Millions Reportedly Mulling Substantial Ticket Price Increase

— April 16, 2024 — 6 Comments -

Nearly Abandoned Mall Outside Vegas Soon to Have Only One Tenant

— March 12, 2024 — 5 Comments

No comments yet